SPG power generation system, providing optimum performance, reliability, and versatility for stationery standby, prime power, and continuous duty applications. All generator sets are prototype tested, factory build, and production tested.

ISO8528 - This generator set has been designed to meet ISO 8528 regulation.

ISO 9001 - This generator set is manufactured in facilities certified to ISO 9001.

This generator set is available with CE certification

This generator set is available with CE certification

Enclosed product is tested according to EU noise legislation 2000/14/EC

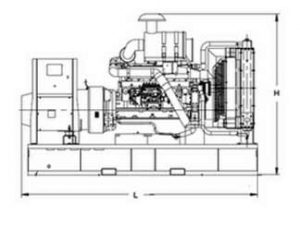

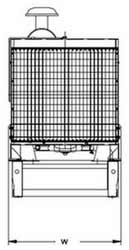

| Open Type | ||

|---|---|---|

| Dimensions (LxWxH) | mm | 2336x1100x1652 |

| Dry Weight | kg | 1780 |

| Sound Attenuated Type | ||

| Dimensions (LxWxH) | mm | 3267x1163x1858 |

| Dry Weight | kg | 2280 |

| Voltage | Standby Rating (ESP) | Prime Rating (PRP) | ||

|---|---|---|---|---|

| kVA | kW | kVA | kW | |

| 400/230 | 200 | 160 | 180 | 144 |

Standby Rating (ESP) : Continuous running at variable load for duration of an emergency. No overload is permitted on these ratings. In accordance with ISO 3046.

Prime Rating (PRP) : Continuous running at variable load for unlimited periods with 10% overload for 1 hour in any 12 hour period. In accordance with ISO 8528, ISO 3046.

| Manufacturer | Cummins | ||

|---|---|---|---|

| Model | 6CTA8.3G2 | ||

| Engine Power Output at rated rpm | kWm | 180 | |

| HP | 241 | ||

| No. of Cylinders and Build | 6 In Line | ||

| Engine Speed | rpm | 1500 | |

| Aspiration and Cooling | Turbocharged and Aftercooled | ||

| Total Displacement | L | 8.3 | |

| Bore and Stroke | mm x mm | 114x135 | |

| Compression Ratio | 17,3:1 | ||

| Governor | Electronic | ||

| Fuel Consumption at full load | L/hr | 42 | |

| Fuel Tank Capacity | Litre | 350 | |

| Oil Capacity | Litre | 27.6 | |

| Coolant Capacity | L | 41.3 | |

| Radiator Cooling Air | m³ /min. | 186 | |

| Air Intake - Engine | m³ /min. | 12.36 | |

| Exhaust Gas Flow | m³ /min. | 34.68 | |

| Design | Brushless single bearing, revolving field/td> | |

|---|---|---|

| Stator | 2/3 pitch | |

| Rotor | Single bearing, flexible disc | |

| Insulation System | Class H | |

| Standard Temperature Rise | 125 - 163°C Continuous | |

| Exciter type | Self Excited | |

| Phase Rotation | A (U), B (V), C (W) | |

| Alternator Cooling | Direct drive centrifugal blower fan | |

| AC Waveform Total Harmonic Distortion | No load <1.5% Non distorting balanced linear load < 5% | |

| Telephone Influence Factor (TUF) | <50 per NEMA MG-1-22.43 | |

| Telephone Harmonic Factor (THF) | <2% | |

Engine

Remote Radiator Cooling

Electronic governor control

Fuel water separator filter

Low water level alarm

Oil Heater

Alternator

3/4 Pole Output Circuit Breaker

Anti-condensation heater

Control System

Charge ammeter

Transfer Switch 3 Pole

Transfer Switch 4 Pole

Earth Fault, single set

Transfer Switch

Three or four pole contactor

Three of four pole motor operated circuit breaker

Accessories

Automatic or manual fuel filling system

Manual oil drain pump

Low and high fuel level alarm

Residential silencer

Enclosure : weather protective or sound attenuated

Duct adapter (on radiator)

Inlet and outlet motorised louvers

Inlet and outlet acoustic baffles

Trailer

Tool kit for maintenance

1500/3000 hours maintenance kit

Double wall chassis

Supplied with oil and coolant

Battery isolating switch

Main fuel tank

Control supervision and protection panel is mounted on the genset base frame. The control panel is equipped as follows:

The module is used to monitor mains supply and starts and stops of a standby generating set

Micro-processor based design

Automatic control of main and generator contactors

Monitors engine performance and AC power output LED alarm indication

Front panel configuration of timers and alarm trip points

CAN and magnetic pick-up versions(specify on ordering)

4 digital inputs/3 analogue inputs

6 outputs(4 configurable on Magnetic Pick-up, 6 configurable onCANbus version)

Easy push button control STOP/RESET -MANUAL -AUTO -TEST –START

Generator Volts (L-L / L-N)

Engine oil pressure (PSI-Bar)

Generator Ampere (L1,L2,L3)

Engine temperature (°C&°F)

Generator Frequency (Hz)

Plant battery volts

Engine hours run

Mains Volts (Ph-Ph/Ph-N)

Over and Under Speed

Low and High Battery Volt

Start and Stop Failure

Charge fail

Over Current

Under / Over Generator Voltage

Low Oil Pressure

Emergency stop

High engine temperature

Mains available

Generator available

Mains on load

Generator on load